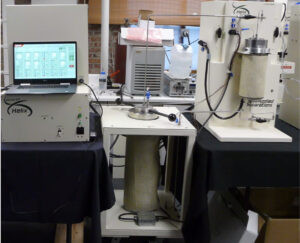

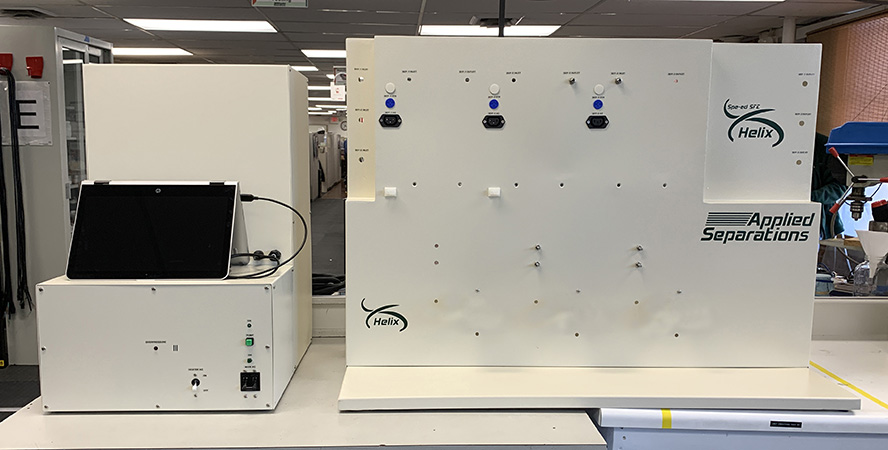

The Helix™ Laboratory Supercritical Process Development Unit is a modular system designed for maximum flexibility and scalability. Depending on your needs, this unit can be configured to handle a multitude of tasks, using only the modules you require for your specific process.

The Helix allows for changing process development needs and budgets. All modules can be purchased initially or new modules can be seamlessly added to the unit as development needs change or budgets allow.

Scalability and flexibility provide the opportunity to focus on what matters most in the lab- output. Should future needs require a new module, that module will be compatible with the original Helix basic system.

ASI’s innovative research and development engineering staff is continuously and diligently working to introduce new Helix™ System modules to provide more value for the technical budget dollar.

Helix Configurations

- Basic Helix - Helix CO2 Extraction System with No CO2 Separators

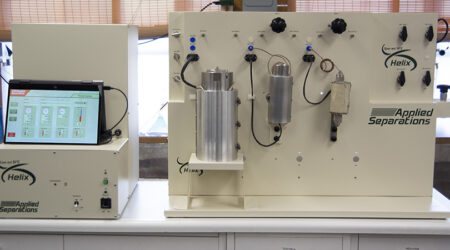

- Helix CO2 Extraction System with 1 CO2 Separator

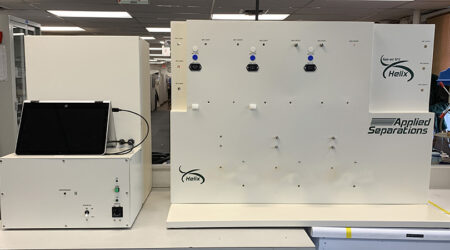

- Helix CO2 Extraction System with 2 CO2 Separators

- Helix Extraction System with 3 CO2 Separators

- temperatures to 240°C

- pressure up to 10,000 psi (690 BAR)

- holds 24mL to 1L vessels standard; up to 5 liter available

- pump flow rates up to 400mL/min*

- fully-adjustable, non-clogging, variable restrictors

- collection into SPE cartridges or standard glassware

- in-line trapping capabilities

- modifier addition capability

- multiple flow path

- extract directly from liquid samples

- stirrer capability

- view cell…capability to look inside of the vessel

- configurations for multiple/varied applications,

check applications sections

*flow rate based on incompressible liquid

Current modules available include:

- Extraction Vessels

- Ranging to 1000 mL with operational pressures of up to 10,000 psi/690 BAR

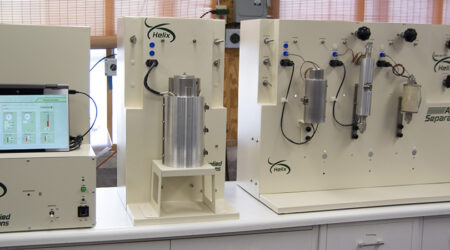

- Cyclonic Separators

- CO2 Pump

- Available in both air and electric drive

- CO2 Recycle

- An environmentally alternative to releasing CO2 into the atmosphere

- Modifier Pump

- Available to add additional catalysts to the SCF process

Helix modules can be specially configured to complete SCF operations including:

- Separations

- Extractions

- Textile Dying

- Aerogel Drying

- Nano size particle generation

- Fragrance extraction

- Essential oil extraction

- IC Wafer cleaning; electronic components and machine parts

Helix modules can also be configured to:

- Subcritical water extraction

- Use alternate gases in place of CO2

Helix System features include

• Variable temperature control to 240°; pressure to 10,000 PSI/690 BAR

• Pump: 400 mL/min. flow rate for atmospheric (incompressible) liquid (Available upgrade to 800mL/min.)

• Extraction vessel assembly sizes: 1000mL, 500mL, 300mL

• Cyclonic separator vessel assembly sizes: 1000mL, 500mL, 300mL

• Independent temperature and pressure controls for extraction and separation vessel modules

• Stirrer addition capability (optional stirrer assembly) (multiple impeller head options available)

• 12” x 22” (30.48 cm x 55.88 cm) base unit footprint.

Pressure Vessels and Separators

Pressure Vessels and Separators

Pressure vessels are heated by specially designed heater assemblies (“clamshell”) that accurately control the temperature.

An additional CO2 preheater is employed to ensure that the CO2 is at the designed temperature before entering the pressure vessel.

A back pressure regulator controls the flow rate of gaseous CO2 if exiting to ambient collection or regulating the pressure in a downstream pressure vessel (e.g. cyclone separator).